Covering Flex Duct With Insulation

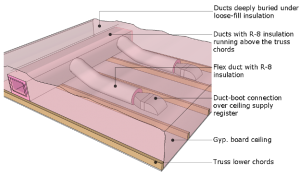

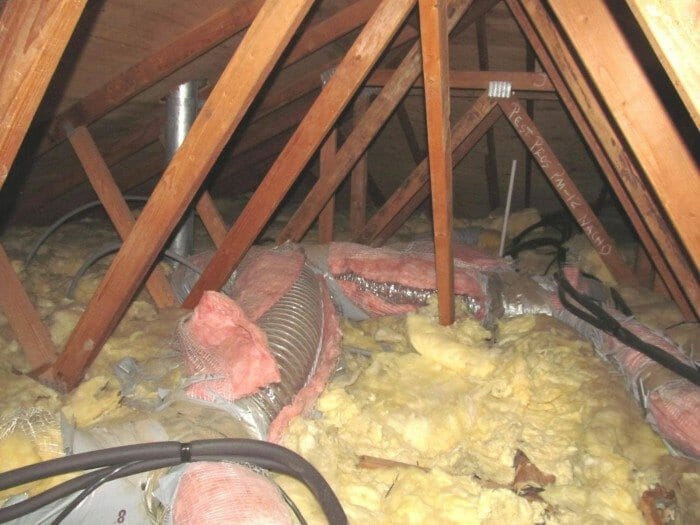

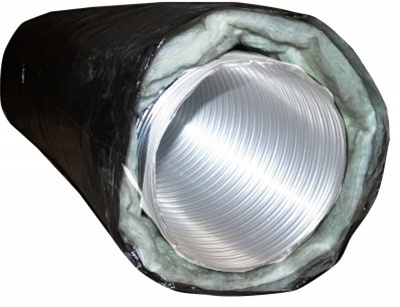

The best way to address poorly insulated attic ducts is to replace older flex duct with newer flex duct with a higher r value at least r 8.

Covering flex duct with insulation. The duct insulation should include a vapor barrier cover. Clear away clutter that blocks your access to the air ducts. Install loose fill insulation to cover the ducts and the attic floor to meet or exceed the code required r value for attic insulation. Use on rectangular and round ductwork.

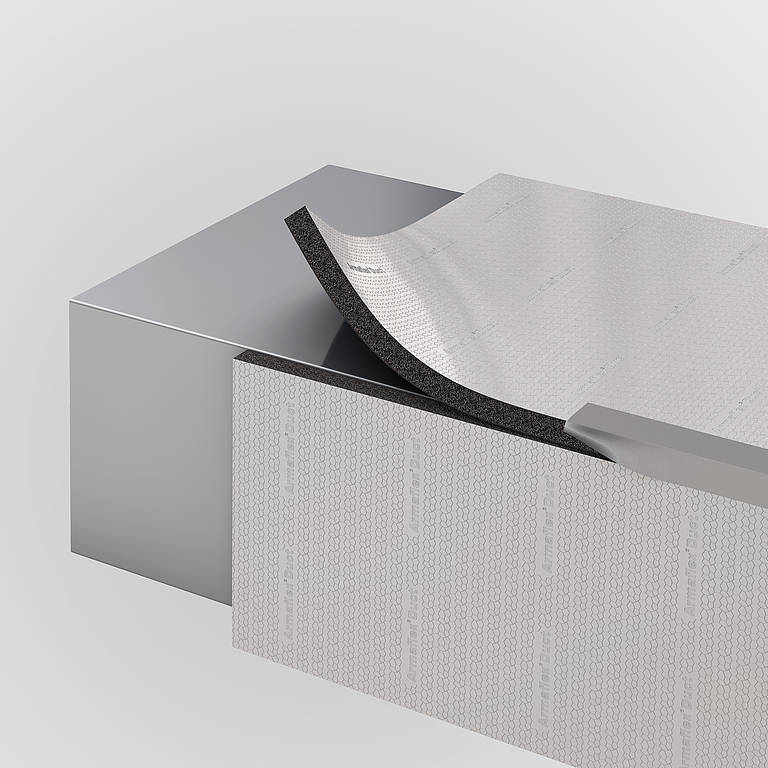

In some cases the insulation is flex board which itself is the pipe or duct. We offer a range of fiberglass duct wrap solutions that provide traditional sheet metal ducts with improved thermal insulation. Cover the metal ductwork with closed cell spray foam. Our duct wrap is available in a variety of densities thicknesses and with or without facings.

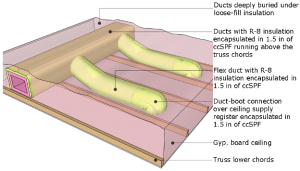

Pull insulation and outer liner over the joint and seal to the attached duct or boot with mastic or foil tape figure 5. Cut a second length of standard insulation batt to the length of the horizontal duct to cover the duct s underside. If you want to cover metal ductwork with blown in insulation t hese steps must be followed in this order. If you need to bury the ducts in insulation the only safe way to do it is to first install a 2 inch layer of closed cell spray foam on the outside of the ducts.

In the example given for the best results we recommend first insulating the lower surface of the duct then the side walls and lastly the top. If there is damage to the metal or flex pipe duct repair it first. Duct insulation sheets typically used as duct wrap these flexible sheets consist of polyethylene bubbles covered with aluminum polyester foil that prevent 96 of heat from radiating into or away from duct. Download brochure pdf v 1540886844000 6 23 mb.

The foam provides a vapor barrier so the ductwork won t sweat. 2 cut a piece of foil tape large enough to cover. How to cover round air ducts with insulation 1. Consider adding more insulation as ductwork is farther from the furnace.

Apply k flex contact adhesive to the insulation surface and to the duct surface. Mechanically fasten and mastic seal all duct connections. If it s uninsulated you should insulated it to at least r 4 to r 8 for dfw. Installing contractors prefer it for many reasons including improved handling easier cutting and less dust.

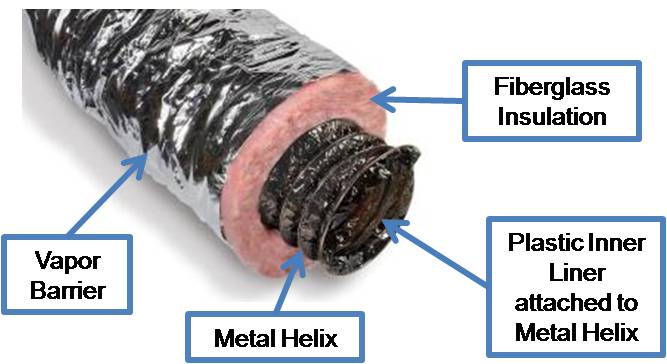

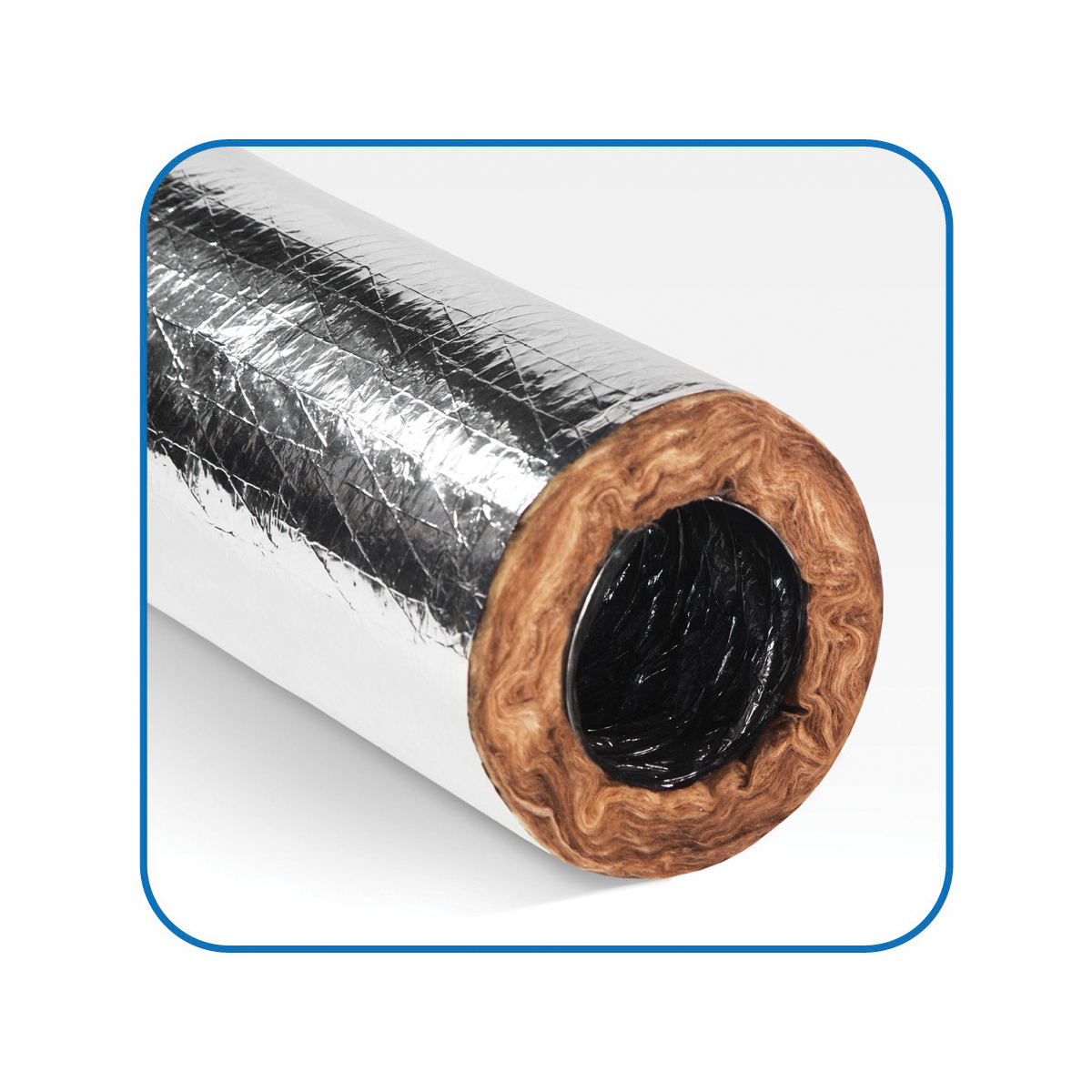

Add additional sealant if necessary. Ecotouch insulation for flexible duct owens corning ecotouch insulation for flexible duct is a lightweight flexible resilient thermal and acoustical insulation made of inorganic glass fibers bonded with a thermosetting resin. The cost and effort to add more insulation is minimal. To attach flex duct pull back the outer liner fasten the inner liner over the collar with a tool tightened tension tie and mastic seal the connection.

Cover the spray foam with fire retardant spray.